1成果简介

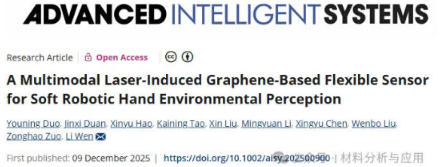

人类皮肤具有复杂的分层结构,其上分布着多样化的感觉受体,使我们在与环境交互时能够感知丰富的多模态信息。这种生物学范式启发了先进多模态柔性传感器和智能机器人系统的研发。本文,北京航空航天大学文力 教授等在《ADVANCED INTELLIGENT SYSTEMS》期刊发表名为“A Multimodal Laser-Induced Graphene-Based Flexible Sensor for Soft Robotic Hand Environmental Perception”的论文,研究提出提出一种基于激光诱导石墨烯(LIG)的新型多模态柔性传感器(MLFS),通过激光加工技术快速制备具有可调特性的LIG功能层。通过整合摩擦电与压阻机制,该柔性传感器可全面检测邻近及接触刺激,提供灵敏可靠的环境反馈。

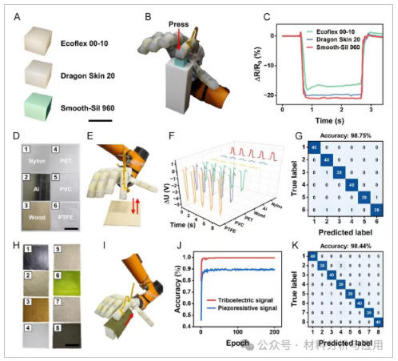

传感器无缝嵌入柔性机器人手指,赋予机械手增强的环境感知与物体辨识能力。实验验证表明,该柔性机器人系统无需视觉引导即可自主执行物体搜索与抓取任务。此外,通过卷积神经网络(CNN)实现物体材质与纹理的高精度分类,准确率分别达98.75%和98.44%。本研究显著提升了软体机器人系统的感知智能,为多模态传感技术与自适应软体机器人融合开辟了坚实路径,彰显其在自主操作与人机交互领域的应用潜力。

2图文导读

图1、Schematic overview of the MLFS-integrated soft robotic system, including multimodal sensing and CNN-based classification for object perception.

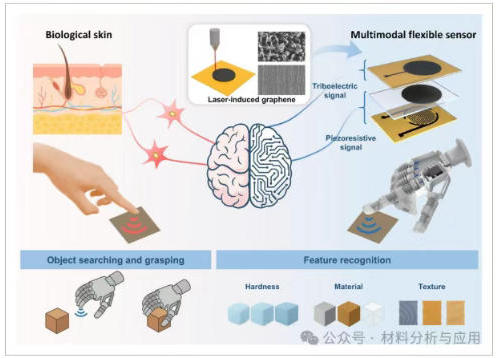

图2、Design and fabrication of the MLFS. A) Optical image of LIG pattern at PPI?=?500 under different laser power conditions. Scale bar: 5?mm. B) Optical image of LIG pattern at PPI?=?1000 under different laser power conditions. Scale bar: 5?mm. C) Raman spectra of LIG fabricated at PPI?=?500 under different laser parameters. D) Raman spectra of LIG fabricated at PPI?=?1000 under different laser parameters. E) Sheet resistance of LIG under different PPI and laser power. F) 3D schematic illustration of the MLFS structure, consisting of triboelectric, piezoresistive, and interdigitated electrode layers. G) Photograph of the fabricated MLFS. Scale bar: 5?mm. H) Fabrication process of the triboelectric layer. I) Fabrication process of the interdigitated electrode layer. J) Fabrication of the piezoresistive layer.

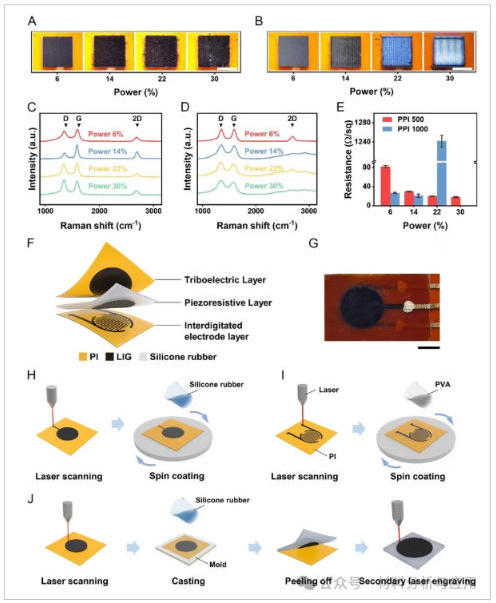

图3、Mechanism and performance of single electrode triboelectric sensing in the case of vertical contact-separation. A) Working principle of the triboelectric sensing layer for proximity and contact detection in the case of vertical contact-separation. B) Potential distribution of COMSOL simulation results in the case of vertical contact-separation. C) Schematic of the test setup used for triboelectric sensing characterization. D) Open-circuit voltage output versus distance curve of triboelectric sensing. E) Sensor output voltage under varying contact pressures up to 100?kPa. F) Short-circuit current response under different loading frequencies. G) Response and recovery time of the triboelectric sensing under fast tapping. H) Cyclic durability test of the triboelectric sensing under repeated loading. Error bars represent standard deviation, n?=?5 independent replicates.

图4、Mechanism and performance of piezoresistive sensing. A) Surface SEM image of piezoresistive layer with laser-engraved microstructures. Scale bar: 500?μm. B) Cross-sectional microscopic image showing the bump structure from secondary laser engraving. Scale bar: 500?μm. C) Working principle of the piezoresistive sensing mechanism under pressure. D) Comparison of resistance-pressure response with and without microstructures. E) Resistance response under different pressures. F) Dynamic response of the piezoresistive sensing under varying frequency loads. G) Response and recovery times of the piezoresistive sensing. H) Demonstration of ultra-low force detection using a 0.3?g metal nut. I) Cyclic durability of the piezoresistive signal under 10?kPa repeated loading. Error bars represent standard deviation, n?=?5 independent replicates.

图5、Soft robotic hand searching and grasping integrated with the MLFS. A) Design of the soft robotic hand with five fingers and six degrees of freedom. Scale bar: 20?mm. B) Structure and actuation mechanism of the soft robotic finger. C) Workflow of autonomous object searching and grasping using MLFS signals. D) Sensor signals during the process. The process is divided into three stages—search, alignment, and grasp.

图6、Soft robotic hand integrated with the MLFS detecting different object properties. A) Silicone blocks made of different hardness silicone materials. Scale bar: 20?mm. B) Experimental setup for hardness discrimination using silicone blocks. C) Sensor response for hardness discrimination using silicone blocks. D) Six materials used for material classification experiments. Scale bar: 50?mm. E) Experimental setup for material classification. F) Triboelectric voltage waveforms from five repeated trials. G) Confusion matrix of CNN-based material classification results (accuracy: 98.75%). H) Eight types of cloth used for texture classification experiments. Scale bar: 50?mm. I) Experimental setup for texture classification. J) Comparison of accuracy rates on the validation set using different signals. K) Confusion matrix of CNN-based texture classification results (accuracy: 98.44%).

3小结

本研究提出一种基于激光诱导石墨烯的多模态柔性传感器,其采用分层结构设计。通过调节激光参数,制备出不同传感层并集成于单一器件中,该器件融合了摩擦电与压阻机制,实现了接近信号与接触信号的有效解耦。实验结果表明,该传感器具有优异的灵敏度、快速响应时间和良好的循环稳定性。该传感器被集成至仿生软体机械手中,使机器人系统能在无外部视觉辅助的情况下实现主动物体搜索、非接触定位及接触式抓取。通过将传感器输出与卷积神经网络(CNN)结合,系统在材料识别与纹理识别任务中分别达到98.75%和98.44%的高分类准确率,展现出强大的智能感知能力。

然而当前传感器与机器人系统仍存在局限:多模态传感器可检测的物理刺激类型有限,难以完全满足非结构化环境中精细操作的复杂感知需求;任务执行过程中切向力、扭矩及温度等关键信息的感知能力尚待提升。此外,目前仅实现单点感知,而获取更丰富信息需依赖大面积传感器阵列。

未来工作将聚焦于多模态传感器与机器人平台的以下扩展优化:首先,计划探索柔性导电复合材料的新型制备技术,开发提升环境感知能力的大面积多模态传感器阵列。其次,旨在将传感器与控制系统、信号处理单元及能源管理模块集成,构建紧凑型低功耗无线通信自感知软体机器人平台。最后,通过融合先进神经网络架构与强化学习算法,使系统能在复杂动态环境中自主调整策略完成任务,从而推动智能机器人领域多模态传感技术的实际应用。

文献: