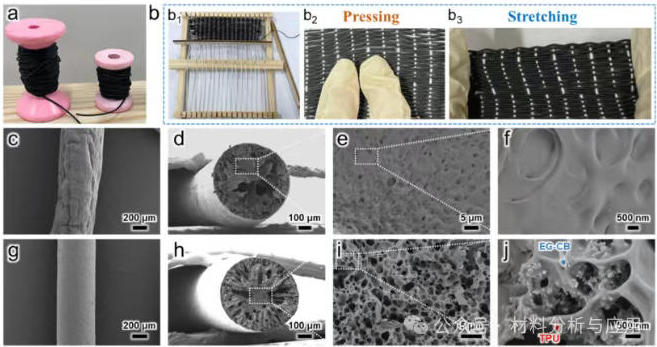

图2. (a) Photograph of CB-EG/TPU fibers continuously collected onto a roller. (b) Images of hand-woven fabrics prepared using manually plied warp and weft fibers, demonstrating their behavior under compressive and tensile deformation. SEM images of the surface (c) and cross-sectional sections (d–f) of pure TPU fiber. SEM images of the surface (g) and cross-sectional sections (h–j) of CB-EG/TPU fibers.

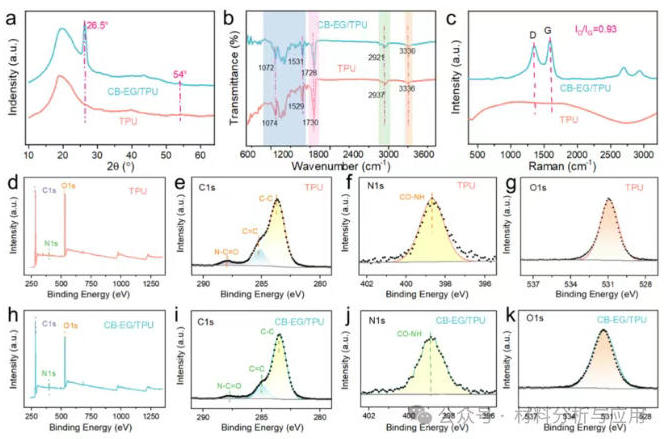

图3. (a) XRD pattern, (b) FTIR spectra, and (c) Raman spectra of pure TPU fiber and CB-EG/TPU fiber. (d) XPS survey scans of the pristine TPU, and (e–g) C1s high-resolution spectrum. (h) XPS survey scans of the pristine CB-EG/TPU, and (i–k) C1s high-resolution spectrum.

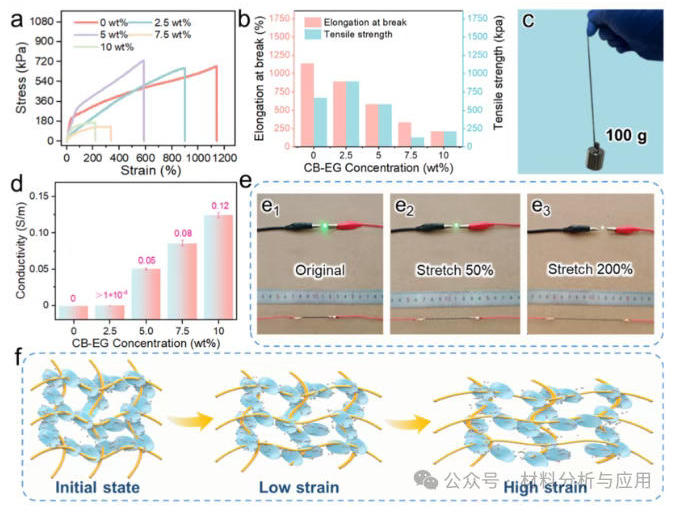

图4. (a) Stress-strain curves of CB-EG/TPU fibers with varying CB-EG contents and (b) corresponding elongation at break and tensile strength. (c) CB-EG/TPU fiber (~570 μm diameter) lifting a 100 g weight. (d) Conductivity as a function of CB-EG concentration. (e) LED brightness modulation of the fiber under tensile strain. (f) Schematic of the microstructural changes in the CB-EG/TPU fiber during stretching.

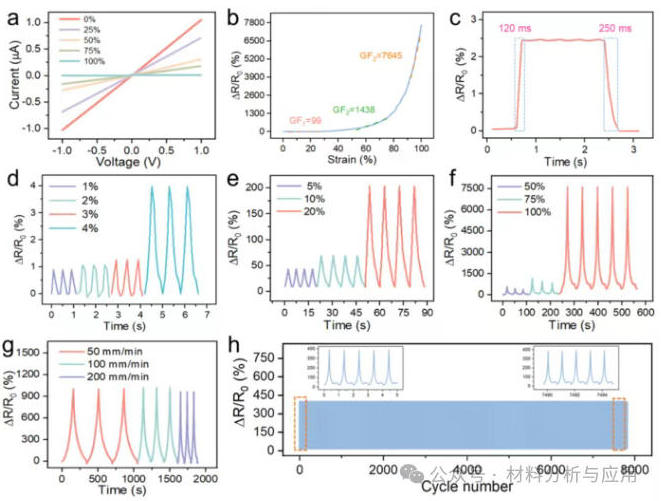

图5. (a) I–V curves under various strains, (b) resistive response, and (c) response time of the CB-EG/TPU fiber strain sensor. Relative resistance changes at (d) weak, (e) small, (f) large strains, and (g) different tensile frequencies. (h) Long-term performance stability over 8000 stretching cycles at 50 % strain.

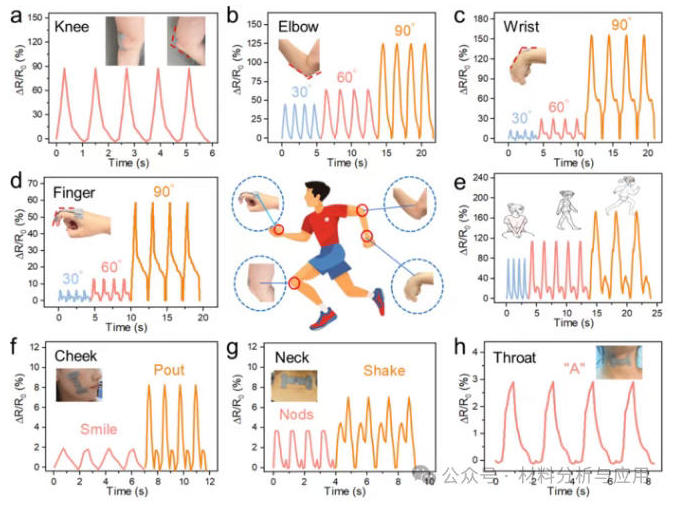

图6. Schematic illustration of the CB-EG/TPU fiber sensor for real-time body movement detection. (a–h) Relative resistance changes were obtained from the motions of the knee, elbow, wrists, bent finger, general movement, cheek, neck, and throat.